-

-

-

--------------------------------- 2368 - A Pencil in Our Economy

-

- We all take so much for granted in our daily lives. We are perishing for want of wonder, not of want of wonders. There are wonders all around us but we fail to see them.

-

- It turns out that not a single person on the face of this Earth knows how to make a pencil. But, it is so simple. Here in lies a lesson that could save the world.

-

- Let’s make a pencil. It looks simple. Let’s see, there is wood, a little lacquer, a small label printed on it, a #2 graphite lead, a bit of metal and an eraser. That’s all. Simple enough.

-

- Let’s start with the wood. Obviously it comes from a tree. In his case a cedar tree in Northern California was chosen for its straight grain. Now, can you stop and imagine all the men and machinery it took to harvest that tree out of the California forest.

-

- Then, of course, all the men and machinery needed to make the lumbering machines and the trucks to haul the trees. Then , to make all the food and clothing for the lumberjacks and truck drivers.

-

- The trucks haul the trees to the railroad which hauls it to San Leandro, California. In San Leandro the logs go to a mill that cuts the cedar into slats that are the length of a pencil and ¼ inch in thickness.

-

- They are kiln dried and tinted so as not to be pallid white in color. The slats are waxed and kiln dried again. The milling operation takes thousands of people for not just the mill but for the concrete dam and the hydropower from Pacific Gas and Electric that runs the factory.

-

- The slats go on railroad cars to several pencil factories across the nation. This pencil is made in a $4,000,000 factory with building and machinery to take each slat and install eight groves.

-

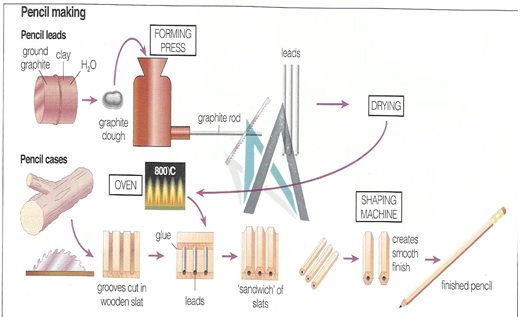

- Next another machine lays leads in every other slat. Applies glue, another machine places another slat on top and creates a lead sandwich. Eight pencils are in a wood-clinched sandwich.

-

- The pencil lead is not really lead it is graphite that came from a mine in Ceylon, Sir Lanka. The miners took the graphite out of the ground and shipped it in paper bags to ships in their harbor.

-

- The ships made there way across the Pacific to the U.S. The graphite is mixed with clay from Mississippi in which ammonium hydroxide is used in the refining process. Then suffocated tallow, a wetting agent, is used. This comes from animal fats that are reacted with sulfuric acid.

-

- The mixture finally gets extruded from a machine, like a sausage. It gets cut to size and baked for several hours at 1,850 degrees F. To increase the lead’s strength and smoothness it is treated with a hot mixture of candilla wax from Mexico, paraffin wax, a by product of petroleum, and hydrogenated natural fats.

-

- Before its next step the cedar wood receives six coats of lacquer. Lacquer comes form castor beans and the refiners of castor oil.

-

- The label comes from a film formed by applying heat to carbon-black mixed with resins.

-

- The metal on the pencil is called a ferrule. It is brass. Now, we have people mining zinc and copper to create the brass in another manufacturing factory. The black rings around the ferrule are black nickel.

-

- Next comes the erasure which has an ingredient called factice. It is a rubber-like product made by reacting rapeseed oil from the Dutch East Indies, Indonesia, with sulfur chloride.

-

- Rubber is only used for binding purposes. There are vulcanizing and accelerating agents added. The pumice comes from Italy. The pink pigment is cadmium sulfide.

-

- Can you now agree that no single person on the face of this Earth knows how to make this pencil. In fact, millions of people had a hand in making this pencil. Each person contributes an infinitesimal bit of know-how to the total system.

-

- Only the sixth grader wanted the pencil. All those millions of people who contributed in the system , none of them wanted a pencil. Many of them never saw a pencil. Each of these millions of people sees that he can exchange his bit of know-how for goods and services contributing to the system involved in making a pencil.

-

- Here comes the lesson: There is no master-mind direction all of this. It is an Invisible Hand. We say only God can make a tree. Well, only an Invisible Hand can make a pencil. It turn out that a pencil is a complex combination of miracles.

-

- Miracles that manifest themselves in nature, trees, ore and chemicals in the ground, water and electricity. But another miracle that manifests itself as the Invisible Hand that is the configuration of all this million creative human energies. All configured to meet a human need embodied in a sixth grader.

-

- The lesson is that human know-how will naturally and automatically arrange themselves into creative and productive patterns in response to the human need of a sixth grader.

-

- The essential ingredient in the system is freedom and the faith in free people. For this reason, an economy can never go into recession. To repeat, an economy can never go into recession by itself.

-

- An economy is motivated by growth and prosperity. Only government intervention into the economy, or, a coercive master-mind can create a recession in an economy.

-

- If only more citizens and more political representatives can learn this lesson that a pencil can teach us. I hope it was worth the read.

-

- May 16, 2019. 1030

----------------------------------------------------------------------------------------

----- Comments appreciated and Pass it on to whomever is interested. ----

--- Some reviews are at: -------------- http://jdetrick.blogspot.com -----

-- email feedback, corrections, request for copies or Index of all reviews

--- to: ------ jamesdetrick@comcast.net ------ “Jim Detrick” -----------

- https://plus.google.com/u/0/ -- www.facebook.com -- www.twitter.com

--------------------- Thursday, May 16, 2019 -------------------------

-----------------------------------------------------------------------------------------

No comments:

Post a Comment